Rostec Plus Digitalization of the Whole Country

Digital transformation is a global megatrend that Russia takes part in along with other leading countries. Enterprises of Rostec state corporation are leaders in a number of priority breakthrough areas. Among them are the digitalization of urban economy, transportation, ‘digital factories’, and cyber threat protection systems.

Digitalization is a priority strategic direction for the development of the national economy, which should ensure the technological sovereignty and competitiveness of the country for decades to come.

Unmanned Technology

The development of unmanned vehicles − cars and aircraft − is another global driver for the development of digital technology. Russia is following a global trend here, although the law has not formally regulated the traffic of unmanned vehicles on urban highways so far, and urban wireless data networks have not reached the 5G level.

Under these conditions, Rostec is developing unmanned technology in the industrial segment. The leading developer in this sphere is Kamaz. So, back in 2016, in collaboration with the NAMI research institute, the concept of the Kamaz-1221 SHUTTLE urban unmanned vehicle was developed and first introduced to the public. And at the end of last year, tests of the Kamaz-4308 Odyssey unmanned truck, which at this stage is used to transport components for local production, began on the inner territory of the Kama Automobile Plant. For this purpose, a 5G network was deployed on the territory of the plant − the first one in Russia.

“The unmanned truck that began to work on the site of the enterprise is highly accurate – navigation error does not exceed three to five centimeters,” said Sergey Chemezov, head of Rostec state corporation and chairman of the board of directors of Kamaz. “The launch of the project is a significant event, not only for the Russian automotive industry but also for the industry as a whole. This may become the first step toward the robotization of industrial equipment, including those operating in extreme conditions − for example, in mines, quarries, and in the Far North.” Further development of commercial unmanned transport projects and the speed of their launch on the market will depend on a number of conditions, including the adoption of relevant legislation and the deployment of fifth-generation communication networks. At the same time, unmanned technologies for business are actively developing in Russia. Rostec enterprises have also brought to the market several notable developments.

Thus, ZALA Aero Group (part of the Kalashnikov Group of Companies) has developed and put into commercial operation an air monitoring system for oil pipelines, power lines, and production infrastructure based on ZALA unmanned aerial vehicles. In particular, the ZALA 421-16E UAV controls the condition of more than 250 kilometers of oil field pipelines at the Gazpromneft-Khantos fields in Yugra. This helps to monitor the integrity of highways and the situation at production facilities, to minimize environmental risks, and to identify possible sources of ignition during a fire hazard period.

Today, the use of unmanned aircraft is part of the standard technological process of the largest oil and gas enterprises in Russia − Rosneft, Gazprom, Gazprom Neft, LUKOIL, and Transneft. The drones created by ZALA Aero Group are recognized as one of the best in this segment.

The main practical goals and objectives of Russia’s digitalization strategy are integrated into national projects. Their implementation, with the active support of the state, should lead to a significant increase in the activity of digitalizing business processes, services, and production in the relevant sectors, throughout the economy as a whole. Rostec is one of the key players in the field of Russian digital transformation. The enterprises that are part of the state corporation are involved in the implementation of most national projects where the digitalization agenda is being addressed. At the same time, there are several areas in which, as Rostec experts note, digitalization can lead to the most significant breakthroughs. It is in these areas that the main efforts and resources of the state corporation are concentrated.

Megapolis with Intelligence

Since 2016, the state corporation, as an operator, has been implementing one of the flagship projects in the development of Russian urban agglomerations − Smart City. Within its framework, it is planned to create and implement complex systems, an intelligent digital urban infrastructure to improve the quality of life as well as the security and energy efficiency of Russian cities. Pilot projects for the implementation of Smart City elements have been launched in several Russian cities, including Ulan-Ude, Nizhny Tagil, and Moscow, and have already confirmed their high efficiency.

Work is underway in several main spheres. Transportation is one of the key elements of the urban ecosystem. Logistics set the pace of urban life. Road safety and good transportation accessibility are key indicators of the city’s standard of living and economic development.

In the digital age, traffic management is being automated. It is assumed by the Intelligent Transport System (ITS) − a ‘smart’ integrated mechanism based on innovative developments − to solve various problems of the urban economy, such as to regulate traffic flows, to unclog roads, to make them safer, and to ensure uninterrupted traffic of ground passenger transport.

Rostec enterprises develop, create, and maintain equipment for ITS. These are traffic lights and controllers, video surveillance cameras, ‘smart’ lamps, pedestrian navigation systems, payment systems, weight and size control systems, telecommunications, and other elements of the system. Shvabe holding has installed ‘smart’ traffic lights, traffic sensors, and photo and video recording systems in Moscow and other cities; video surveillance systems of Roselectronika with video analytics function in the public transport in the Kemerovo region and in Saint-Petersburg. Based on the experience of implementing these systems, Roselectronika holding has developed a complex project − a multifunctional intelligent transport video system. The project was presented at the end of last year. The system monitors the safety of passengers, the technical condition of the vehicle, the actions of drivers and conductors, and transmits information about traffic to electronic displays at bus stops.

The system also has the function of monitoring the condition of drivers − ‘Antisleep’. When the engine starts, the equipment automatically identifies the driver’s face. If, according to his facial expressions, eye and head movements, the device determines that the driver is falling asleep or distracted from the road, then sound and light signals turn on. Information about the driver’s condition and actions is also transmitted to the monitoring center.

When used in railway transport, the system is able to read traffic signals, to determine the condition of switches, to recognize foreign objects on rails, and, if necessary, to initiate emergency braking.

“The new system of intelligent video monitoring is characterized by wide functionality and, in fact, has no analogs. With its help, the carrier receives a range of opportunities in the field of security, personnel control, and passenger flow metering,” confirms Oleg Evtushenko, executive director of Rostec. “The system is easily replicated and can be modified to meet the requirements of any customers. In particular, this project has already been adapted for use in subways and at railways.”

Rostec is actively involved in the development of the Moscow Intelligent Transport System (ITS);Shvabe holding provides services to the Moscow ITS under a contract valid until 2023. Overall, the company controls 3,700 traffic monitoring sensors, more than 2,800 traffic lights, 175 road displays, 2,700 television surveillance cameras, and 48 weather stations, information from which is collected in real time and analyzed by the Center for Traffic Management’s Situation Center. In total, ITS servers process information and control the work of more than 175,000 vehicles − public transportation, taxis, and car-sharing vehicles. The creation and operation of the system were based on world best practices.

“When we took on the introduction of ITS in Moscow, we certainly turned to the experience of foreign colleagues, but found out that many of their solutions were simply not suitable for Russia,” commented Rostec’s deputy general director, Alexander Nazarov. “As a result, many projects appeared at our production facilities − this applies to both technical solutions and software.”

The corporation not only implements and maintains the elements of ITS but also evaluates their effectiveness, and also makes recommendations for the development of the system. So, at the end of 2019, the joint venture of Rostec and JSC GLONASS, the company GLONASS – Road Safety, evaluated the effectiveness of road cameras in Russian regions. Using its own software and hardware complex, the company analyzed the effectiveness of more than 15,000 stationary complexes of photo and video recording of traffic rules violations on Russian roads over the past five years. Moscow became the leader among the cities with a high density of road cameras: Since 2010, the number of recorded accidents in the capital has decreased by 23%, while the number of cars in the Moscow metropolitan area has increased by 1.2 million units during this time. The next step will be recommendations for the installation of new photo and video recording systems based on the analysis of big data using artificial intelligence.

Since 2016, the state corporation, as an operator, has been implementing one of the flagship projects in the development of Russian urban agglomerations − Smart City. Within its framework, it is planned to create and implement complex systems, an intelligent digital urban infrastructure to improve the quality of life as well as the security and energy efficiency of Russian cities. Pilot projects for the implementation of Smart City elements have been launched in several Russian cities, including Ulan-Ude, Nizhny Tagil, and Moscow, and have already confirmed their high efficiency.

Work is underway in several main spheres. Transportation is one of the key elements of the urban ecosystem. Logistics set the pace of urban life. Road safety and good transportation accessibility are key indicators of the city’s standard of living and economic development.

In the digital age, traffic management is being automated. It is assumed by the Intelligent Transport System (ITS) − a ‘smart’ integrated mechanism based on innovative developments − to solve various problems of the urban economy, such as to regulate traffic flows, to unclog roads, to make them safer, and to ensure uninterrupted traffic of ground passenger transport.

Rostec enterprises develop, create, and maintain equipment for ITS. These are traffic lights and controllers, video surveillance cameras, ‘smart’ lamps, pedestrian navigation systems, payment systems, weight and size control systems, telecommunications, and other elements of the system. Shvabe holding has installed ‘smart’ traffic lights, traffic sensors, and photo and video recording systems in Moscow and other cities; video surveillance systems of Roselectronika with video analytics function in the public transport in the Kemerovo region and in Saint-Petersburg. Based on the experience of implementing these systems, Roselectronika holding has developed a complex project − a multifunctional intelligent transport video system. The project was presented at the end of last year. The system monitors the safety of passengers, the technical condition of the vehicle, the actions of drivers and conductors, and transmits information about traffic to electronic displays at bus stops.

The system also has the function of monitoring the condition of drivers − ‘Antisleep’. When the engine starts, the equipment automatically identifies the driver’s face. If, according to his facial expressions, eye and head movements, the device determines that the driver is falling asleep or distracted from the road, then sound and light signals turn on. Information about the driver’s condition and actions is also transmitted to the monitoring center.

When used in railway transport, the system is able to read traffic signals, to determine the condition of switches, to recognize foreign objects on rails, and, if necessary, to initiate emergency braking.

“The new system of intelligent video monitoring is characterized by wide functionality and, in fact, has no analogs. With its help, the carrier receives a range of opportunities in the field of security, personnel control, and passenger flow metering,” confirms Oleg Evtushenko, executive director of Rostec. “The system is easily replicated and can be modified to meet the requirements of any customers. In particular, this project has already been adapted for use in subways and at railways.”

Rostec is actively involved in the development of the Moscow Intelligent Transport System (ITS);Shvabe holding provides services to the Moscow ITS under a contract valid until 2023. Overall, the company controls 3,700 traffic monitoring sensors, more than 2,800 traffic lights, 175 road displays, 2,700 television surveillance cameras, and 48 weather stations, information from which is collected in real time and analyzed by the Center for Traffic Management’s Situation Center. In total, ITS servers process information and control the work of more than 175,000 vehicles − public transportation, taxis, and car-sharing vehicles. The creation and operation of the system were based on world best practices.

“When we took on the introduction of ITS in Moscow, we certainly turned to the experience of foreign colleagues, but found out that many of their solutions were simply not suitable for Russia,” commented Rostec’s deputy general director, Alexander Nazarov. “As a result, many projects appeared at our production facilities − this applies to both technical solutions and software.”

The corporation not only implements and maintains the elements of ITS but also evaluates their effectiveness, and also makes recommendations for the development of the system. So, at the end of 2019, the joint venture of Rostec and JSC GLONASS, the company GLONASS – Road Safety, evaluated the effectiveness of road cameras in Russian regions. Using its own software and hardware complex, the company analyzed the effectiveness of more than 15,000 stationary complexes of photo and video recording of traffic rules violations on Russian roads over the past five years. Moscow became the leader among the cities with a high density of road cameras: Since 2010, the number of recorded accidents in the capital has decreased by 23%, while the number of cars in the Moscow metropolitan area has increased by 1.2 million units during this time. The next step will be recommendations for the installation of new photo and video recording systems based on the analysis of big data using artificial intelligence.

Bright and Safe

Modern energy and lighting systems are other key elements of the Smart City, the introduction of which in the urban economy leads to a significant increase in its effectiveness. This is proved, in particular, by the results of the project ‘Bright City – Nizhny Tagil’. Reconstruction of the city lighting system has already reduced energy consumption by more than 20 million kilowatts per year. More than 13,000 energy-saving lamps were installed in the streets of the city, and more than 400 kilometers of distribution and supply networks were laid; now a new stage of work begins.

In its turn, last December, Shvabe holding, which is part of Rostec, and the Siberian-Ural Energy Company signed a strategic partnership agreement, in accordance with which they intend to create an intelligent outdoor lighting system in Tobolsk, with the possibility of further replication of these solutions in the municipalities of the Tyumen region. The key priorities in this work will be saving electric energy, as well as improving the index of urban environment quality, environmental safety, and living comfort.

Implementation of this project may be the first step and the basis for the integrated digitalization of the entire urban environment of Tobolsk and other cities in the region. In the future, there are plans to develop an intelligent transport system (ITS) and weight control on regional roads.

“Within the framework of the project, we propose upgrading over 11,000 objects of the outdoor lighting system. In addition, proposals for the development of existing systems for improving security, the development of ITS, and fixing offenses have been prepared for implementation,” says Ivan Ozhgykhin, deputy general director of Shvabe for the development of sales, marketing, and service support systems for civilian products. “As a result, we expect to reduce the city budget costs for the maintenance of the lighting system and, among other things, to reduce the accident rate by thirty to forty percent.”

Besides Tobolsk, where the Bright City program is just at its launch, it is already being implemented in a number of Russian cities – in Nizhny Tagil, Ulan-Ude, and St. Petersburg. Creating the architecture of city lighting, the corporation focuses on the best foreign and Russian experiences: Paris, Shanghai, Toronto, Lyon, and Mexico City serve as examples. In Moscow, such a project was a new system of architectural and artistic lighting at three large objects of the Moscow Central Ring − Luzhnetskiy, Dorogomilovskiy, and Danilovskiy bridges.

‘Safe City’ is another significant element of the Smart City that involves the deployment of infrastructure in cities and the creation of monitoring systems, public alerts, and quick response to emergencies. The use of such systems reduces street crime and vandalism by 1.5 to three times. One of the structural components of a ‘safe city’ is FindFace Security. It is a software package for the recognition and analysis of biometric data, developed by Rostec’s technology partner NtechLab.

By analyzing video streams, the NtechLab solution reveals the correspondence of persons in the frame with the control databases in real time and with high accuracy. When a match is found, security officers receive instant alerts. The effectiveness of this solution was proved during the 2018 FIFA World Cup, when more than 100 people included in the delinquent databases were detained thanks to its use.

Today, the NtechLab solution is widely used to ensure public safety during sports and entertainment events, in industrial enterprises and in retail organizations. The complex is used at transport infrastructure facilities to collect and analyze anonymized statistical data as well as to ensure transportation safety.

Modern energy and lighting systems are other key elements of the Smart City, the introduction of which in the urban economy leads to a significant increase in its effectiveness. This is proved, in particular, by the results of the project ‘Bright City – Nizhny Tagil’. Reconstruction of the city lighting system has already reduced energy consumption by more than 20 million kilowatts per year. More than 13,000 energy-saving lamps were installed in the streets of the city, and more than 400 kilometers of distribution and supply networks were laid; now a new stage of work begins.

In its turn, last December, Shvabe holding, which is part of Rostec, and the Siberian-Ural Energy Company signed a strategic partnership agreement, in accordance with which they intend to create an intelligent outdoor lighting system in Tobolsk, with the possibility of further replication of these solutions in the municipalities of the Tyumen region. The key priorities in this work will be saving electric energy, as well as improving the index of urban environment quality, environmental safety, and living comfort.

Implementation of this project may be the first step and the basis for the integrated digitalization of the entire urban environment of Tobolsk and other cities in the region. In the future, there are plans to develop an intelligent transport system (ITS) and weight control on regional roads.

“Within the framework of the project, we propose upgrading over 11,000 objects of the outdoor lighting system. In addition, proposals for the development of existing systems for improving security, the development of ITS, and fixing offenses have been prepared for implementation,” says Ivan Ozhgykhin, deputy general director of Shvabe for the development of sales, marketing, and service support systems for civilian products. “As a result, we expect to reduce the city budget costs for the maintenance of the lighting system and, among other things, to reduce the accident rate by thirty to forty percent.”

Besides Tobolsk, where the Bright City program is just at its launch, it is already being implemented in a number of Russian cities – in Nizhny Tagil, Ulan-Ude, and St. Petersburg. Creating the architecture of city lighting, the corporation focuses on the best foreign and Russian experiences: Paris, Shanghai, Toronto, Lyon, and Mexico City serve as examples. In Moscow, such a project was a new system of architectural and artistic lighting at three large objects of the Moscow Central Ring − Luzhnetskiy, Dorogomilovskiy, and Danilovskiy bridges.

‘Safe City’ is another significant element of the Smart City that involves the deployment of infrastructure in cities and the creation of monitoring systems, public alerts, and quick response to emergencies. The use of such systems reduces street crime and vandalism by 1.5 to three times. One of the structural components of a ‘safe city’ is FindFace Security. It is a software package for the recognition and analysis of biometric data, developed by Rostec’s technology partner NtechLab.

By analyzing video streams, the NtechLab solution reveals the correspondence of persons in the frame with the control databases in real time and with high accuracy. When a match is found, security officers receive instant alerts. The effectiveness of this solution was proved during the 2018 FIFA World Cup, when more than 100 people included in the delinquent databases were detained thanks to its use.

Today, the NtechLab solution is widely used to ensure public safety during sports and entertainment events, in industrial enterprises and in retail organizations. The complex is used at transport infrastructure facilities to collect and analyze anonymized statistical data as well as to ensure transportation safety.

Unmanned Technology

The development of unmanned vehicles − cars and aircraft − is another global driver for the development of digital technology. Russia is following a global trend here, although the law has not formally regulated the traffic of unmanned vehicles on urban highways so far, and urban wireless data networks have not reached the 5G level.

Under these conditions, Rostec is developing unmanned technology in the industrial segment. The leading developer in this sphere is Kamaz. So, back in 2016, in collaboration with the NAMI research institute, the concept of the Kamaz-1221 SHUTTLE urban unmanned vehicle was developed and first introduced to the public. And at the end of last year, tests of the Kamaz-4308 Odyssey unmanned truck, which at this stage is used to transport components for local production, began on the inner territory of the Kama Automobile Plant. For this purpose, a 5G network was deployed on the territory of the plant − the first one in Russia.

“The unmanned truck that began to work on the site of the enterprise is highly accurate – navigation error does not exceed three to five centimeters,” said Sergey Chemezov, head of Rostec state corporation and chairman of the board of directors of Kamaz. “The launch of the project is a significant event, not only for the Russian automotive industry but also for the industry as a whole. This may become the first step toward the robotization of industrial equipment, including those operating in extreme conditions − for example, in mines, quarries, and in the Far North.” Further development of commercial unmanned transport projects and the speed of their launch on the market will depend on a number of conditions, including the adoption of relevant legislation and the deployment of fifth-generation communication networks. At the same time, unmanned technologies for business are actively developing in Russia. Rostec enterprises have also brought to the market several notable developments.

Thus, ZALA Aero Group (part of the Kalashnikov Group of Companies) has developed and put into commercial operation an air monitoring system for oil pipelines, power lines, and production infrastructure based on ZALA unmanned aerial vehicles. In particular, the ZALA 421-16E UAV controls the condition of more than 250 kilometers of oil field pipelines at the Gazpromneft-Khantos fields in Yugra. This helps to monitor the integrity of highways and the situation at production facilities, to minimize environmental risks, and to identify possible sources of ignition during a fire hazard period.

Today, the use of unmanned aircraft is part of the standard technological process of the largest oil and gas enterprises in Russia − Rosneft, Gazprom, Gazprom Neft, LUKOIL, and Transneft. The drones created by ZALA Aero Group are recognized as one of the best in this segment.

In its turn, Avtomatika concern has developed its own solution for the automatic monitoring of extended infrastructure facilities − special software using ultra-precise neural networks. The data source for this software is unmanned aerial vehicles, and the subject of monitoring is linear objects, primarily overhead power lines. Images obtained from cameras of visible, ultraviolet, and infrared spectra mounted on UAVs are processed and analyzed to determine the parameters of the object and to identify possible defects and inconsistencies.

Digital Factory

Unmanned vehicles are only one of the elements of production based on a digit, that is one of the ‘digital factories’ of the future. Today, as part of the digital transformation, a wide program of technical re-equipment of the major Russian industrial enterprises has been launched: New workshops are fully equipped with digital technology, industrial digital counterparts of individual manufacturers, and entire enterprises are being introduced.

The introduction of these technologies, among other things, solve the problem of increasing labor productivity.

Thus, in 2019, one of the most highly automated enterprises in Russia started operating in Naberezhnye Chelny − the truck frame factory within the framework of Kamaz and Daimler joint venture. The new production is designed to manufacture 55,000 products per year, which will be delivered to the Kamaz conveyor and assembly production of Mercedes-Benz trucks.

This production has the highest level of automation in Russia and operates on the principles of clear logistics and lean production. A highly automated welding workshop, an automatic system for loading truck cabs into specialized trailers for their further transportation to assembly lines − all these latest technologies were implemented at this production facility for the first time in our country.

Last fall, Rostec launched a large-scale modernization program for one of the leading enterprises in the military-industrial complex − Kurganmashzavod (KMZ). By the end of 2020, the plant will receive more than 30 high-precision digital CNC machines, which will double the output of civilian products. In particular, parts for cross-country vehicles.

In their turn, the specialists of the National Center for Informatization (NCI), a member of Rostec, have begun to develop a digital transformation program for more than 700 state-owned enterprises. One of the key decisions will be the creation of infrastructure for the use of a digital counterpart technology − a computer model that allows predicting the life cycle of an object, equipment operation, wear of elements, and service intervals. In addition, it will help to prevent errors even at the stage of equipment design, as well as to reduce the cost of its maintenance within 20%.

Until now, in Russian practice, this technology has been used mainly in the oil industry, including for modeling wells, equipment, and field development projects. Recently, ‘digital counterparts’ have been actively introduced in other industries, including the enterprises of the United Engine Corporation. For the first time, elements of this technology were used to create the SaM-146 engine. They are also used as part of the PD-14 engine project and in the development of offshore gas turbine engines. The United Engine Corporation implements ‘digital counterparts’ in the framework of agreements with its partners: Central Institute of Aviation Motors (CIAM), St. Petersburg Polytechnic University (SPbPU), Sarov Engineering Center, and other organizations.

Last December, the first stage of the project for the development of the ‘digital counterpart’ was announced, and the testing ground of the TV7-117ST-01 engine, commissioned by ODK-Klimov, was completed. The uniqueness of this project lies in an integrated approach to the complete formalization of the design process of a gas turbine engine; when all the controlled parameters and target values are described in detail, the calculation models created during product design are interlinked. In fact, this is the first Russian example of redesigning a gas turbine engine based on the ‘digital counterpart’ technology with digitizing the company’s many years of experience in the field of engine development: from basic experiments and determining the properties of materials to describing the physical and mechanical parameters of product operation.

Unmanned vehicles are only one of the elements of production based on a digit, that is one of the ‘digital factories’ of the future. Today, as part of the digital transformation, a wide program of technical re-equipment of the major Russian industrial enterprises has been launched: New workshops are fully equipped with digital technology, industrial digital counterparts of individual manufacturers, and entire enterprises are being introduced.

The introduction of these technologies, among other things, solve the problem of increasing labor productivity.

Thus, in 2019, one of the most highly automated enterprises in Russia started operating in Naberezhnye Chelny − the truck frame factory within the framework of Kamaz and Daimler joint venture. The new production is designed to manufacture 55,000 products per year, which will be delivered to the Kamaz conveyor and assembly production of Mercedes-Benz trucks.

This production has the highest level of automation in Russia and operates on the principles of clear logistics and lean production. A highly automated welding workshop, an automatic system for loading truck cabs into specialized trailers for their further transportation to assembly lines − all these latest technologies were implemented at this production facility for the first time in our country.

Last fall, Rostec launched a large-scale modernization program for one of the leading enterprises in the military-industrial complex − Kurganmashzavod (KMZ). By the end of 2020, the plant will receive more than 30 high-precision digital CNC machines, which will double the output of civilian products. In particular, parts for cross-country vehicles.

In their turn, the specialists of the National Center for Informatization (NCI), a member of Rostec, have begun to develop a digital transformation program for more than 700 state-owned enterprises. One of the key decisions will be the creation of infrastructure for the use of a digital counterpart technology − a computer model that allows predicting the life cycle of an object, equipment operation, wear of elements, and service intervals. In addition, it will help to prevent errors even at the stage of equipment design, as well as to reduce the cost of its maintenance within 20%.

Until now, in Russian practice, this technology has been used mainly in the oil industry, including for modeling wells, equipment, and field development projects. Recently, ‘digital counterparts’ have been actively introduced in other industries, including the enterprises of the United Engine Corporation. For the first time, elements of this technology were used to create the SaM-146 engine. They are also used as part of the PD-14 engine project and in the development of offshore gas turbine engines. The United Engine Corporation implements ‘digital counterparts’ in the framework of agreements with its partners: Central Institute of Aviation Motors (CIAM), St. Petersburg Polytechnic University (SPbPU), Sarov Engineering Center, and other organizations.

Last December, the first stage of the project for the development of the ‘digital counterpart’ was announced, and the testing ground of the TV7-117ST-01 engine, commissioned by ODK-Klimov, was completed. The uniqueness of this project lies in an integrated approach to the complete formalization of the design process of a gas turbine engine; when all the controlled parameters and target values are described in detail, the calculation models created during product design are interlinked. In fact, this is the first Russian example of redesigning a gas turbine engine based on the ‘digital counterpart’ technology with digitizing the company’s many years of experience in the field of engine development: from basic experiments and determining the properties of materials to describing the physical and mechanical parameters of product operation.

Blades and 3D

Rostec created one of the first ‘factories of the future’ in Russia in Rybinsk: At the end of last year, the corporation opened Russia’s largest center for the production of turbine blades for aircraft, marine, and industrial engines on the base of the local company ODK-Saturn. Innovative production will allow the annual production of components for more than 2,000 power plants, both Russian and foreign.

“The turbine blade is one of the most knowledge-intensive and difficult to manufacture components of gas turbine engines for aviation, marine vessels, and energy. Only six countries in the world produce such products. It requires complex calculations in the design and very high precision in manufacturing. New digital technologies introduced at the UEC allow us to produce world-class products,” says Vladimir Artyakov, first deputy general director of Rostec. “At the same time, production accuracy increases by thirty percent, the cost of blades is reduced by fifty percent, and labor costs are reduced by forty percent. The project, without exaggeration, takes Russian engine construction to a new level and allows it to claim a leading position in this high-tech segment.”

In 2020, the UEC enterprise will double production volumes − up to 280,000 blades per year, and by 2024, the center’s productivity should grow seven times: It is planned to produce about 900,000 blades at its capacities, including those produced for foreign customers.

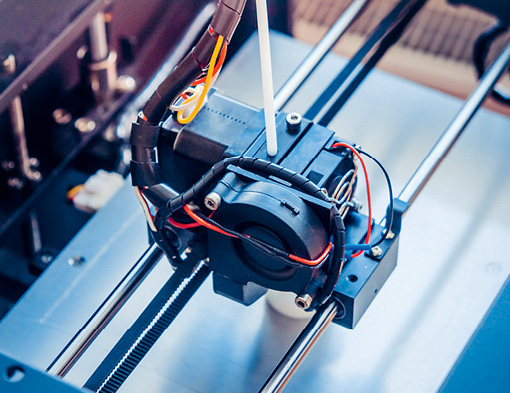

The latest technologies of ‘digital production’ is another important area that Rostec pays special attention to. It also includes industrial 3D printing technology. The application of a new approach to design and production on this technological base allows the reduction of the number of structural parts, reducing the weight of the product by about a quarter and the production time by half. Cost reductions can exceed 40%.

To develop this direction, Rostec, with the participation of the holdings of its aircraft cluster − the United Engine Corporation, Russian Helicopters, Technodinamika and KRET − created the Center for Additive Technologies (CAT) on the basis of Moscow Machine-Building Enterprise named after V.V. Chernyshev (part of the UEC). Its main task is the introduction of industrial 3D printing in high-tech industries. The CAT is already working on engine parts, elements of the fuel system, and other components for aviation.

“Industrial 3D printing is becoming one of the indispensable attributes of modern industry. We see this technology’s high potential and are introducing it into our production practice,” says Anatoly Serdyukov, Rostec aviation cluster industrial director. “The creation of a specialized center has allowed us to expand the scope of this technology and to produce parts for industries such as aircraft manufacturing, space, high-tech medicine, and the automotive industry.”

Last fall, with the participation of the CAT, a unique international training program for advanced technologies in the field of additive manufacturing, Additive Minds, was launched in Russia. Mentors and teachers here are practicing engineers with experience in leading European companies.

Rostec created one of the first ‘factories of the future’ in Russia in Rybinsk: At the end of last year, the corporation opened Russia’s largest center for the production of turbine blades for aircraft, marine, and industrial engines on the base of the local company ODK-Saturn. Innovative production will allow the annual production of components for more than 2,000 power plants, both Russian and foreign.

“The turbine blade is one of the most knowledge-intensive and difficult to manufacture components of gas turbine engines for aviation, marine vessels, and energy. Only six countries in the world produce such products. It requires complex calculations in the design and very high precision in manufacturing. New digital technologies introduced at the UEC allow us to produce world-class products,” says Vladimir Artyakov, first deputy general director of Rostec. “At the same time, production accuracy increases by thirty percent, the cost of blades is reduced by fifty percent, and labor costs are reduced by forty percent. The project, without exaggeration, takes Russian engine construction to a new level and allows it to claim a leading position in this high-tech segment.”

In 2020, the UEC enterprise will double production volumes − up to 280,000 blades per year, and by 2024, the center’s productivity should grow seven times: It is planned to produce about 900,000 blades at its capacities, including those produced for foreign customers.

The latest technologies of ‘digital production’ is another important area that Rostec pays special attention to. It also includes industrial 3D printing technology. The application of a new approach to design and production on this technological base allows the reduction of the number of structural parts, reducing the weight of the product by about a quarter and the production time by half. Cost reductions can exceed 40%.

To develop this direction, Rostec, with the participation of the holdings of its aircraft cluster − the United Engine Corporation, Russian Helicopters, Technodinamika and KRET − created the Center for Additive Technologies (CAT) on the basis of Moscow Machine-Building Enterprise named after V.V. Chernyshev (part of the UEC). Its main task is the introduction of industrial 3D printing in high-tech industries. The CAT is already working on engine parts, elements of the fuel system, and other components for aviation.

“Industrial 3D printing is becoming one of the indispensable attributes of modern industry. We see this technology’s high potential and are introducing it into our production practice,” says Anatoly Serdyukov, Rostec aviation cluster industrial director. “The creation of a specialized center has allowed us to expand the scope of this technology and to produce parts for industries such as aircraft manufacturing, space, high-tech medicine, and the automotive industry.”

Last fall, with the participation of the CAT, a unique international training program for advanced technologies in the field of additive manufacturing, Additive Minds, was launched in Russia. Mentors and teachers here are practicing engineers with experience in leading European companies.

Anti-Hacker Solution

Digitalization of the economy is not only saving time and resources but improving the quality of services and labor productivity. The introduction of the ‘digit’ carries well-known risks with it, primarily in the field of cybersecurity. As practice shows, imported digital equipment may contain undocumented functions that allow it to influence its operation in the interests of third parties. In its turn, this may create uncontrolled risks for its operators. For instance, last fall, Gazprom faced a forced remote shutdown via satellite of its compressors supplied earlier by the Austrian LMF. Further use of this equipment for its intended purpose became impossible. The gas concern had to purchase analogs of Russian production to replace it.

In this context, the transition of Russian industrial companies to domestic solutions, software, and equipment increases the reliability of the systems in which they are used. Rostec enterprises are among the suppliers of a wide range of such solutions that ensure the sustainability of critical cybersecurity facilities.

To automate the management of the electric grid complex, Roselectronika holding has introduced intelligent systems of operational dispatch, technological, and situational management of electric networks in Russian regions. They provide data collection on the operation of substation equipment, the reliability of electrical networks, and the organization of remote control of equipment and its maintenance.

Last year, a contract was signed to implement these solutions in several Russian regions at once: in the Omsk and Altai regions, and the Altai and Buryat Republics. “The enterprises of Rostec’s radio and electronic cluster are creating complex solutions for the digitalization of the domestic electric grid complex. Roselectronika holding is already working on the deployment of energy network management systems at the facilities of the Krasnoyarsk region, Kemerovo region, and Trans-Baikal Territory,” notes Oleg Evtushenko, executive director of the state corporation. “The new contract was a continuation of the strategic partnership between Rostec and Rosseti. Its implementation will improve the quality and reliability of energy supply in the regions of Siberia and the Far East. The works are planned to be completed by the end of 2020.”

The domestic software package KOTMI-Rosel will be used to create the system. It allows real-time monitoring of equipment status, processing up to 500,000 measurements per second on a single server.

Telemetry information collected in this way is displayed on video walls in control centers and network control centers, making it possible to instantly respond to emergencies.

KOTMI-Rosel already operates at Krasnoyarskenergo facilities. The system manages more than 100 substations with a voltage of 35–500 kilowatts, 2,000 distribution points and transformer substations with a voltage of 6–10 kilowatts. During the Universiade-2019, the complex provided management of all energy objects of the sports forum.

Replacing imported equipment with domestic analogs is an important − but not the only − part of the complex work to protect against cyber threats. It is necessary to create additional levels of protection against cyberattacks, and Rostec enterprises also present a number of their own solutions here.

Thus, Roselectronika has introduced the first SecureDiode data diode to the market, which provides cybersecurity for IoT equipment monitoring systems and process control systems. SecureDiode is a network device for organizing continuous real-time data transmission between two networks with different security levels − for example, between networks of ministries and departments. It is a gateway between a public and a closed network. The equipment allows the unidirectional transfer of information from a public network to a closed one, guaranteeing information security of protected network space.

Avtomatika concern solutions designed to protect corporate and departmental communication systems provide a high degree of information security.

“Our developments allow us to build a communication system based on Russian equipment that is best resistant to attacks by outsiders and insiders,” says General Director of Avtomatika Vladimir Kabanov. “These products can find demand in the largest state corporations and in enterprises that work with confidential or secret information.”

At the end of last year, the Ministry of Defense of the Russian Federation certified the key components of the Avtomatika complex − the IVA AVES S secure video-conferencing system and the IVA LARGO video terminal. The certificate confirms the compliance of this technology with all the requirements of special customers in the field of information security, including the protection of information marked ‘top secret’. Both developments are completely domestic.

Digitalization of the economy is not only saving time and resources but improving the quality of services and labor productivity. The introduction of the ‘digit’ carries well-known risks with it, primarily in the field of cybersecurity. As practice shows, imported digital equipment may contain undocumented functions that allow it to influence its operation in the interests of third parties. In its turn, this may create uncontrolled risks for its operators. For instance, last fall, Gazprom faced a forced remote shutdown via satellite of its compressors supplied earlier by the Austrian LMF. Further use of this equipment for its intended purpose became impossible. The gas concern had to purchase analogs of Russian production to replace it.

In this context, the transition of Russian industrial companies to domestic solutions, software, and equipment increases the reliability of the systems in which they are used. Rostec enterprises are among the suppliers of a wide range of such solutions that ensure the sustainability of critical cybersecurity facilities.

To automate the management of the electric grid complex, Roselectronika holding has introduced intelligent systems of operational dispatch, technological, and situational management of electric networks in Russian regions. They provide data collection on the operation of substation equipment, the reliability of electrical networks, and the organization of remote control of equipment and its maintenance.

Last year, a contract was signed to implement these solutions in several Russian regions at once: in the Omsk and Altai regions, and the Altai and Buryat Republics. “The enterprises of Rostec’s radio and electronic cluster are creating complex solutions for the digitalization of the domestic electric grid complex. Roselectronika holding is already working on the deployment of energy network management systems at the facilities of the Krasnoyarsk region, Kemerovo region, and Trans-Baikal Territory,” notes Oleg Evtushenko, executive director of the state corporation. “The new contract was a continuation of the strategic partnership between Rostec and Rosseti. Its implementation will improve the quality and reliability of energy supply in the regions of Siberia and the Far East. The works are planned to be completed by the end of 2020.”

The domestic software package KOTMI-Rosel will be used to create the system. It allows real-time monitoring of equipment status, processing up to 500,000 measurements per second on a single server.

Telemetry information collected in this way is displayed on video walls in control centers and network control centers, making it possible to instantly respond to emergencies.

KOTMI-Rosel already operates at Krasnoyarskenergo facilities. The system manages more than 100 substations with a voltage of 35–500 kilowatts, 2,000 distribution points and transformer substations with a voltage of 6–10 kilowatts. During the Universiade-2019, the complex provided management of all energy objects of the sports forum.

Replacing imported equipment with domestic analogs is an important − but not the only − part of the complex work to protect against cyber threats. It is necessary to create additional levels of protection against cyberattacks, and Rostec enterprises also present a number of their own solutions here.

Thus, Roselectronika has introduced the first SecureDiode data diode to the market, which provides cybersecurity for IoT equipment monitoring systems and process control systems. SecureDiode is a network device for organizing continuous real-time data transmission between two networks with different security levels − for example, between networks of ministries and departments. It is a gateway between a public and a closed network. The equipment allows the unidirectional transfer of information from a public network to a closed one, guaranteeing information security of protected network space.

Avtomatika concern solutions designed to protect corporate and departmental communication systems provide a high degree of information security.

“Our developments allow us to build a communication system based on Russian equipment that is best resistant to attacks by outsiders and insiders,” says General Director of Avtomatika Vladimir Kabanov. “These products can find demand in the largest state corporations and in enterprises that work with confidential or secret information.”

At the end of last year, the Ministry of Defense of the Russian Federation certified the key components of the Avtomatika complex − the IVA AVES S secure video-conferencing system and the IVA LARGO video terminal. The certificate confirms the compliance of this technology with all the requirements of special customers in the field of information security, including the protection of information marked ‘top secret’. Both developments are completely domestic.